|

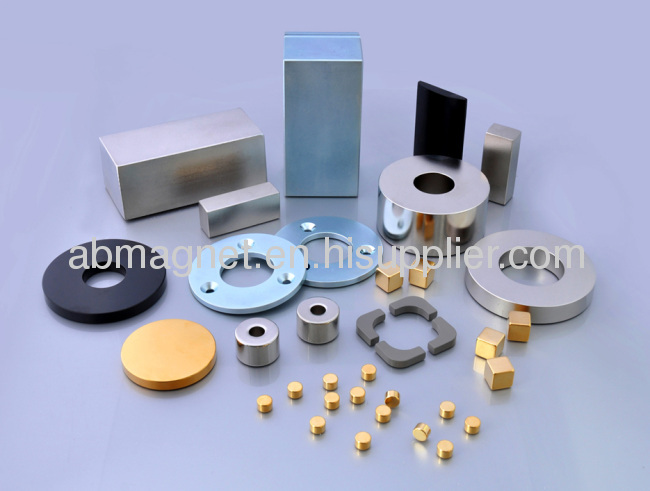

Ningbo Able Magnetic Co., Ltd.

|

Ningbo Able Magnetic Co., Ltd. [China (Mainland)]

Business Type:Manufacturer, Trading Company

City: Ningbo

Province/State: Zhejiang

Country/Region: China (Mainland)